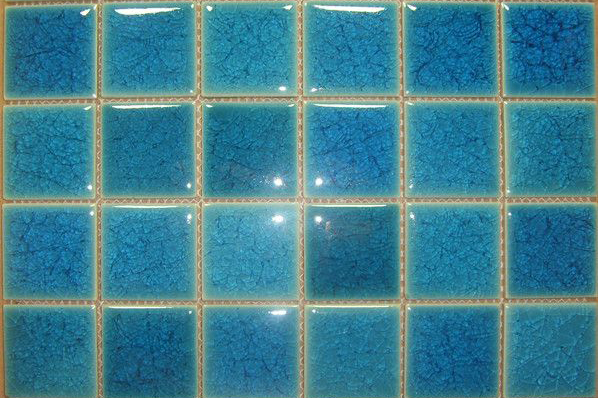

Muaj yeeb yuj enamelled iav chav dej thiab cov phab ntsa sab nrauv muaj

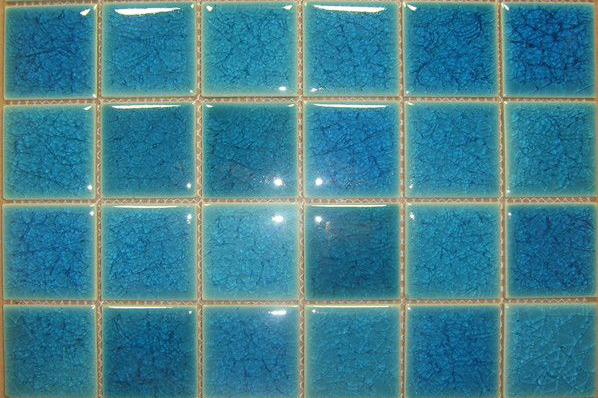

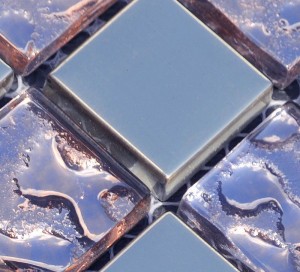

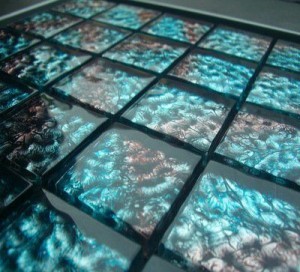

Product Description

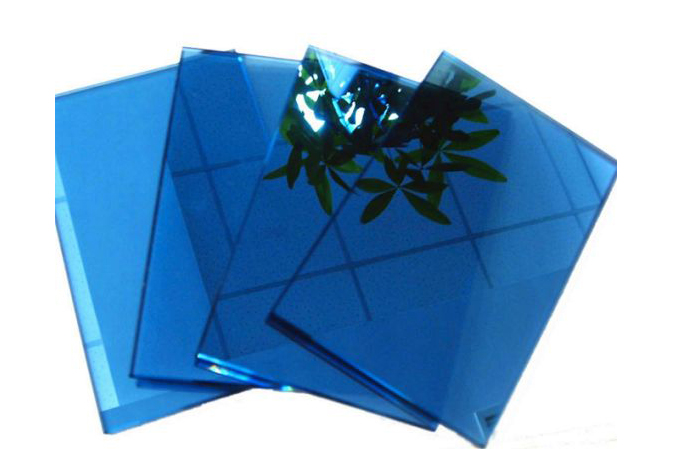

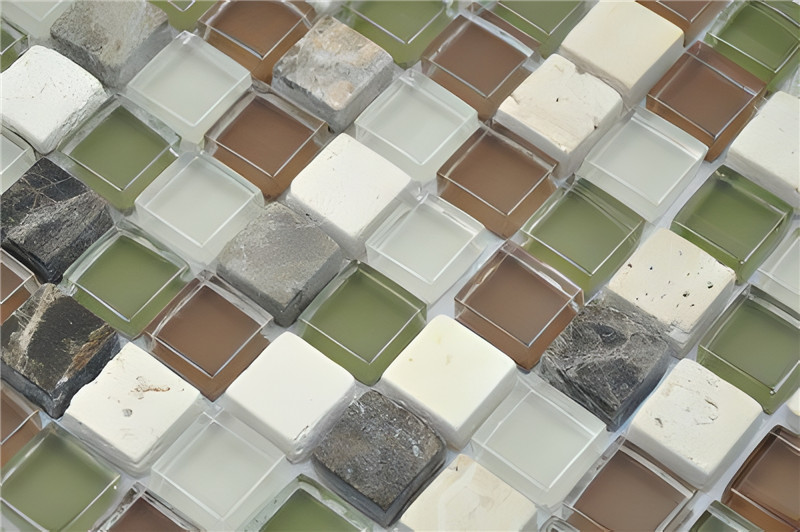

Enamelled iavhais txog cov iav nto txiav hauv ib qho me me coated nrog txheej xim fusible glaze, cua sov rau glaze yaj, kom cov glaze txheej thiab iav khov kho ua ke, los ntawm sintering, annealing los yog tempering txheej txheem,tempered enamel iavua tau zoo nkauj xim thiab qauv. Nws muaj tshuaj lom neeg ruaj khov thiab zoo nkauj, tsim nyog rau kev tsim cov phab ntsa sab nrauv.

Kev tsim cov iav enameled suav nrog kev tsim cov xim glaze, glazing, ziab, cua sov, quenching lossis annealing, txias thiab lwm yam txheej txheem.

Muaj ob yam khoom siv hauv kev tsim cov iav glaze, puag glaze thiab xim, puag glaze yog cov hmoov ntawm fusible iav frit; Pigment yog ib qho xim inorganic. Nws tuaj yeem yog ib qho inorganic compound los yog ob peb inorganic compounds. Nws yog tsim los ntawm kev sib tsoo, sib tov, sintering thiab sib tsoo rau hauv cov hmoov hauv ib qho piv txwv.

(1) Base Glaze

Lub luag hauj lwm ntawm lub hauv paus glaze yog disperse cov inorganic pigment heev, thiab yaj nyob rau saum npoo ntawm iav substrate ntawm qhov kub thiab txias, thiab lub substrate yog integrated rau hauv ib tug tag nrho; Thaum lub hauv paus glaze yog fused, cov xim inorganic nrog lub peev xwm xim muaj zog yuav dye nws mus rau hauv cov xim iav, thiab txheej ntawm iav thiab iav substrate tau muab tso rau hauv ib qho tag nrho thiab dhau los ua cov yeeb yuj glazed iav. Cov kev ua tau zoo ntawm lub hauv paus glaze yog yuav tsum tau: lub melting kub yog tsawg, uas yuav tsum tau melted nyob rau saum npoo ntawm iav substrate ua ntej softening; Nws muaj cov tshuaj lom neeg ruaj khov thiab luster, thiab tsis tsim cov tshuaj lom neeg nrog cov xim inorganic, thiab tsis ua rau cov xim ntawm inorganic pigment nws tus kheej hloov; Lub expansion coefficient yog ze heev rau expansion coefficient ntawm iav substrate. Thaum qhov kub hloov pauv, lub glaze tsis tawg thiab hlawv.

(2) Pigment

Pigment, nws yog ib hom hlau oxides los yog cov tebchaw, kuj tuaj yeem ua los ntawm ntau cov hlau oxides lossis cov khoom sib txuas, raws li ib qho piv txwv ntawm kev sib tsoo, sib tov, sintering, ntxuav, lim, ziab, thiab sib tsoo rau hauv cov hmoov zoo. Ntau yam xim ntawm cov xim, kev xaiv ntawm cov hlau oxide, tsis muaj softening, sintering kub thiab sintering lub sij hawm txawv ntawm cov xim. Lub dispersion ntawm cov xim hauv kev siv muaj kev sib raug zoo nrog nws cov particle loj, qhov me me, qhov ntau dua qhov dispersion (cov particle feem ntau tsawg dua 5 um).

Enamelling

1. Cov txheej txheem yob txheej txheej txheej txheej txheej txheej txheej txheej txheej yog lub hauv paus ntsiab lus ntawm kev hloov yob tshuab luam ntawv, cov xim tuab tuab yog coated rau ntawm qhov chaw ntawm cov iav substrate siv cov menyuam roj hmab.

2. Txoj kev luam ntawv npo Cov txheej txheem yog kev hloov pauv ntawm kev tshuaj ntsuam luam ntawv thev naus laus zis thiab cov cuab yeej siv niaj hnub textile, kev siv tshuaj ntsuam luam ntawv xovxwm, glaze slurry, coated rau ntawm iav substrate ib los yog ntau hom glaze. Hlau mesh yog ua los ntawm hluavtaws fiber ntau lossis stainless hlau xaim.

3. Txoj kev Stamping Txoj kev no siv cov khoom siv hloov tau yooj yim rau hauv cov qauv ntawm lub foob, lub foob nrog ib txheej ntawm cov xim glaze muab tshuaj txhuam, thiab tom qab ntawd luam tawm ntawm lub khob huv si substrate.

4. Txoj kev nplaum nplaum yog ib qho kev txuas ntxiv thiab nthuav dav ntawm txoj kev tshuaj ntsuam luam ntawv. Nws yog los luam tawm cov qauv sib txawv ntawm ntau yam xim hauv qab ntawm ib daim ntawv tshwj xeeb. Thaum siv, dej yog siv los ua ib daim ntawv khi, thiab nws muab tso rau ntawm lub khob huv si, uas yog qhuav thiab tom qab ntawd rhuab.

Qhuav

Tom qab glazing, txheej glaze yuav tsum tau qhuav rau cov kauj ruam tom ntej. Raws li cov txheej txheem glazing thiab ntau lawm, ntuj ziab, chamber hluav taws xob ziab thiab nruam hluav taws xob ziab tuaj yeem xaiv raws li cov txheej txheem ziab.

Cua sov thiab txias

enamelled iav sib npaug cua sov thiab cua txias raws li cov txheej txheem ntau lawm, cov txheej txheem xaiv thiab khoom siv:

1.Txoj kev toughening

Cov txheej txheem ntawm cov txheej txheem toughening yog hloov cov ntawv iav qhuav rau hauv lub qhov cub toughening thiab cua sov rau 670 ~ 715 ℃, thiab tom qab ntawd txav mus rau hauv huab cua los rau quenching.

2.Txoj kev semi-tempering

Semi-tempering method Cov txheej txheem ntawm txoj kev no yog hloov cov ntawv iav qhuav rau hauv lub qhov cub cua sov thiab ua kom sov rau qee qhov kub, thiab tom qab ntawd txav mus rau hauv chav txias kom tswj tau qhov txias. Cov txheej txheem cua sov annealing Nws yog cov ntawv iav qhuav tom qab glazing mus rau hauv ib lub rooj rau cov menyuam tsis tu ncua cua sov cellar, nyob rau hauv kiln tom qab preheating, cua sov, annealing, txias thiab ua los ntawm glazed iav. Qhov siab tshaj plaws kub nyob rau hauv lub kiln yog 670 ~ 715 ℃, thiab ces annealing thiab txias yog nqa tawm raws li ib tug tej yam kub tswj.

Qhov zoo

1.Mechanical zog

Nrog zoo tshuaj stability thiabkho kom zoo nkauj, tuaj yeem ua raws li tus neeg siv khoom xav tau lossis kos duab tsim qauv.

2. Ua kom zoo nkauj zoo nkauj nplua nuj xim

Exquisite qauv, tsis ploj, tsis ploj, yooj yim los ntxuav.

Siv ntau yam

Sab hauv tiav, foyers thiab stairwells ntawm cov tsev dav dav thiab sab nrauv tiav ntawm cov tsev; Shading thiab spacer phab ntsa, cov ntxaij vab tshaus thiab lwm yam khoom siv hauv tsev yuav tsum tau ua los ntawm lub tsev; Glazed iav muab faib qhov cub qhov rooj, qhov cub sab saum toj, countertop thiab superior rooj tog fittings; Glazed iav thav duab teeb ntxoov ntxoo, tawg ntxoov ntxoo, ntxoov ntxoo thiab lwm yam khoom siv teeb pom kev zoo; Glazed iav teeb ntxoov ntxoo tsheb iav ntug, thiab lwm yam.

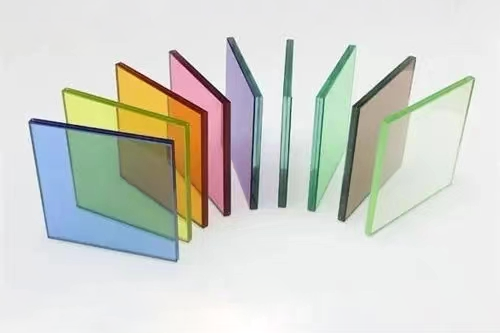

Xim

Inorganic pigments feem ntau siv rau iav luam ntawv number case yog raws li nram no:

1. Liab - cadmium sulfide;

2. daj - lead chromate, cadmium sulfide, uranium ntsev;

3. Ntsuab - chromium oxide;

4. Xiav - cobalt aluminate;

5. Xim av - hlau oxide;

6. Dawb - calcium oxide, kaolin, thiab lwm yam.

7. Dub - iridium oxide, manganese oxide thiab lwm yam sib tov;

Kev Tsim Nyog Tsim Nyog

Lub tuam txhab cov khoom tau dhau lawmTuam Tshoj yuam kev zoo system CCC ntawv pov thawj, Australia AS/NS2208:1996 certification, thiabAustralia AS/NS4666:2012 certification. Ntxiv rau qhov ua tau raws li lub teb chaws cov qauv tsim, tab sis kuj ua tau raws li kev lag luam tawm txawv teb chaws.